The DMME is one of the University of Malta’s best-equipped departments and collaborates with many others. Lars Lorenz meets Dr Ing. Glenn Cassar to find out more.

R

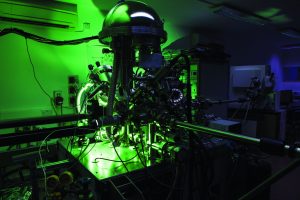

esearch needs expensive, high-end equipment. Measurements need extreme accuracy while microscopes need to peer at the atomic level when analysing materials. To maximise resources items needs to be shared and well managed. Over half a dozen faculties at the University of Malta (UoM) use the Department of Metallurgy and Materials Engineering (DMME)’s equipment according to Dr Ing. Glenn Cassar (Head of DMME).

This is one of the reasons the DMME was outfitted with over €5.5 million worth of equipment over the last 10 years, with a huge chunk coming from a €4.4 million ERDF grant in 2009.

Material engineering is a highly interdisciplinary field. Novel materials designed for hip joints, teeth, automotive parts, tools, and other applications are all tested in collaboration with medics, scientists, and dentists from other faculties. Cassar and his team provide scientific advice and help. They also assist industrial partners, which generate revenue that is entirely reinvested into the laboratory. Doing so allows the DMME team to maintain its equipment to the highest standards.

‘The laboratory’s star piece is the Scanning Electron Microscope (SEM)’, says Cassar. The equipment, priced over €830,000, allows researchers to see the structure of materials down to a magnitude smaller than the width of a human hair. The microscopic world is beautiful to visualise, but this microscope can give detailed information about a material’s chemical composition and surface structure.

Currently the equipment cannot be used at full capacity. The limited space leads to the machines interfering with each other. In the coming years the department will move into a new building specifically designed for their requirements as part of the UoM’s Master Plan.