In the power semiconductor world, especially in applications where there are large currents (tens or hundreds of Amperes) or high switching frequencies (kilohertz or megahertz), the challenge for engineers has always been how to manage the resulting power losses which are generated in the form of heat. Large temperature swings, especially when repeated cyclically over long periods, lead to thermomechanical stresses in the internal joints of the power module, which eventually fail and result in a product fault. This is no less so in the solid state relay (SSR) industry.

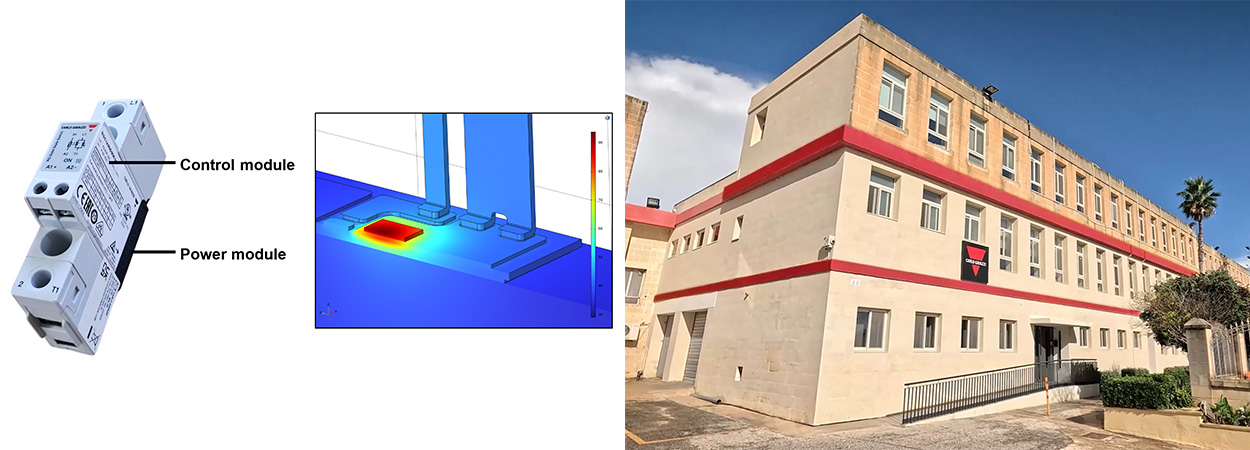

Carlo Gavazzi Ltd. develops and produces solid state relays as its main product group and has been present in Malta since 1978. It includes an R&D group of over 20 persons, one of whose key responsibilities is to develop power modules for the Switches product line. The group collaborates regularly with the University of Malta and sees the possibility of further collaboration specifically in power module development.

With the support of Xjenza Malta through the FUSION: R&I Research Excellence Programme, Carlo Gavazzi has embarked on a research project where a prototype power module which features an innovative topology and state-of-the-art interconnection technology has been designed. This design aims to increase the reliability of the internal joints while making them capable of operating at higher temperatures. A team of engineers and designers within the Carlo Gavazzi R&D group conducted this project. One of the team members is Denise Sciberras, who started out as a student intern with Carlo Gavazzi and graduated as an engineer at UM in 2022. The team collaborated with external partners and suppliers in Europe who supplied the materials and laboratory facilities for the building of the prototypes. The power module samples were then assembled in modified Carlo Gavazzi SSRs and used for electrical characterisation tests. These will be followed by thermal characterisation and reliability tests and compared with current technology. The results of this research project, together with lessons learnt, will be used in a feasibility project currently being conducted by the same team, assessing the benefits of implementing selected features of the new technology in new SSR platforms. The aim is to identify a new power module concept that will give the company a competitive advantage in product performance and cost of production for SSRs that will be industrialised and produced for commercialisation in the global market.

This new power semiconductor package design also opens the door for Carlo Gavazzi to advanced semiconductors such as wide bandgap (SiC MOSFETs and the like). In industrial applications, these semiconductors are capable of switching with very small power losses with the associated economical and environmental benefits. Moreover, it makes it possible to operate with a much smaller heat sink or even completely without a heat sink.

Although naturally numerous challenges were encountered in this research project, all of them were successfully circumvented and in the end a number of functional samples have been assembled with a very high yield, making the project a success.